ASTRO (Autonomous Swarm for Terrestrial Resource Operations)

The A.S.T.R.O. (Autonomous Swarm for Terrestrial Resource Operations) project aims to revolutionize asteroid mining by deploying a fleet of small, autonomous robots inspired by the collective behavior of ants. These “MinerAnts” will work collaboratively to efficiently extract, process, and transport valuable resources from asteroids. The project leverages principles of swarm intelligence, advanced AI, and autonomous systems to ensure high efficiency, resilience, and adaptability. This detailed project plan outlines the design, development, and operational workflow of the A.S.T.R.O. initiative, providing a comprehensive roadmap for its implementation over the next two years.

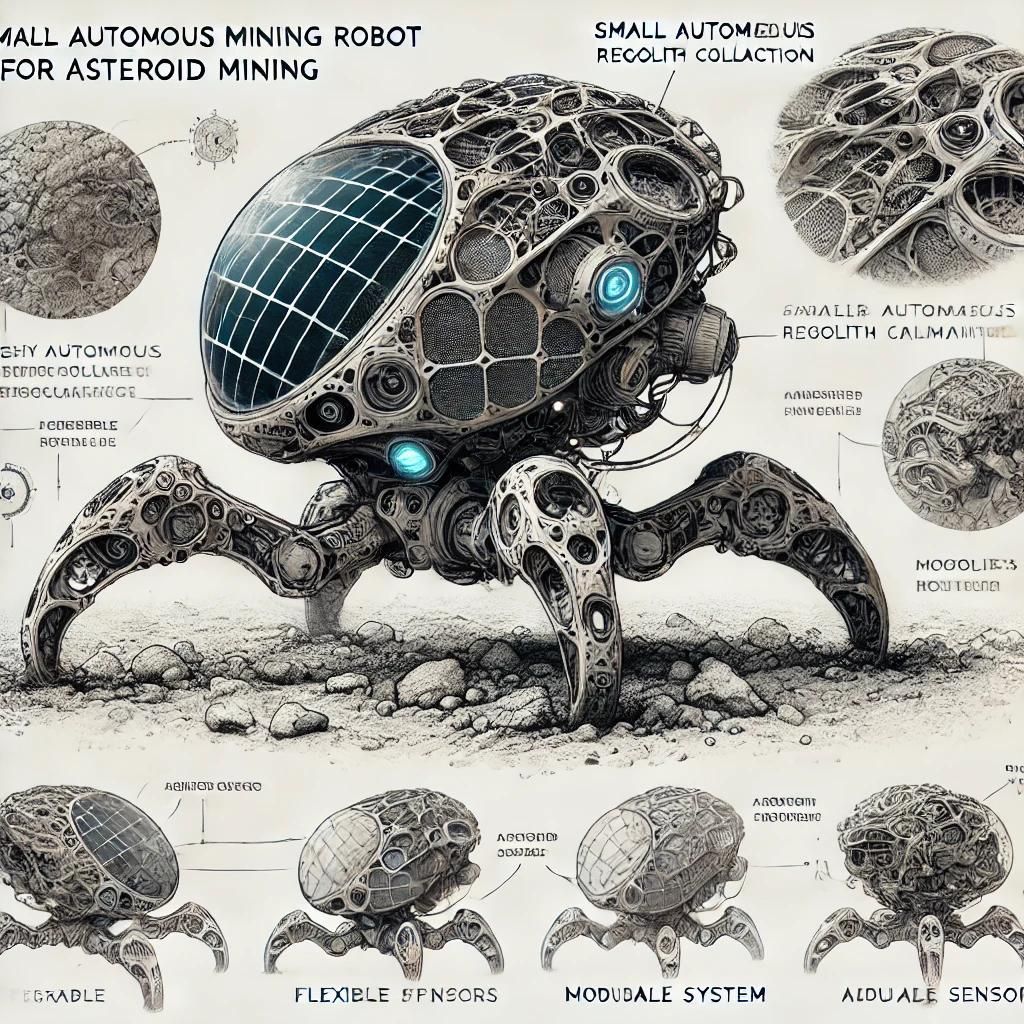

Key Components and Design

1. MinerAnt Robots

- Design: MinerAnts are small, lightweight robots designed to mimic the collaborative behavior of ants. Each robot is equipped with:

- Drills and Scoops: For regolith extraction.

- Sensors: For navigation, environmental analysis, and communication.

- Solar Panels: For primary power supply.

- Batteries: For energy storage during non-solar periods.

- Modular Components: Allowing for easy maintenance and upgrades.

- Dimensions and Build: Each MinerAnt measures approximately 30x30x15 cm, constructed from durable, lightweight alloys that are resistant to radiation and micrometeoroid impacts. The exterior features integrated solar panels that double as protective casings, ensuring both power efficiency and durability.

- Mobility: Equipped with six multi-jointed legs, inspired by ant physiology, the MinerAnts can navigate the uneven and rocky surfaces of asteroids. These legs allow for agile movements and stability, essential for operating in low-gravity environments.

- Communication: MinerAnts are fitted with low-power, high-range communication devices to ensure constant connectivity within the swarm. This enables them to share real-time data on resource locations, environmental conditions, and operational status, ensuring coordinated efforts and efficiency.

2. Swarm Intelligence and Coordination

- Swarm Intelligence: Inspired by ant colonies, MinerAnts use decentralized algorithms to coordinate their activities. This approach allows for dynamic task allocation, where robots can autonomously adjust their roles based on the needs of the operation and the environment. For instance, if one area shows a higher concentration of valuable resources, more MinerAnts will converge on that area to maximize extraction efficiency.

- AI and Machine Learning: Advanced AI systems manage real-time decision-making, navigation, and task allocation. Machine learning enables the robots to improve their operations over time by learning from environmental feedback and previous missions. This adaptive behavior ensures that the MinerAnts become more efficient with each mission, continually optimizing their strategies for resource extraction and processing.

- Communication Network: The communication network is crucial for the success of the swarm. Each MinerAnt is equipped with a robust wireless module that facilitates seamless data exchange. The network supports various communication protocols to ensure reliability and redundancy, essential for maintaining coordination in the challenging environment of space.

3. Mining and Processing Units

- Regolith Extraction: Each MinerAnt is equipped with specialized tools for digging and collecting regolith from the asteroid’s surface. These tools include high-frequency drills and precision scoops designed to handle a variety of soil types and densities. The MinerAnts can penetrate the surface to reach layers rich in valuable minerals, maximizing the efficiency of the mining process.

- Onboard Processing: Once collected, the regolith is processed onboard to separate valuable minerals from waste. This involves a series of automated sorting and refining steps that utilize techniques such as magnetic separation and chemical leaching. By processing the materials on-site, the MinerAnts significantly reduce the mass that needs to be transported back to Earth, making the operation more efficient and cost-effective.

- Transport Shuttles: Autonomous transport shuttles ferry processed materials from the mining site to a central collection point or directly to return modules. These shuttles are equipped with precision landing and docking systems, ensuring safe and efficient transfer of materials even in the low-gravity environment of an asteroid.

4. Energy Management

- Solar Power: High-efficiency solar panels provide continuous power during sunlight exposure. The panels are designed to track the Sun’s position, optimizing energy capture. This feature is particularly useful on asteroids with irregular rotation patterns, ensuring that the MinerAnts remain powered throughout their operations.

- Battery Systems: Advanced batteries store energy for use during periods without sunlight, ensuring uninterrupted operations. These batteries are made from cutting-edge materials that offer high energy density and rapid charging capabilities, allowing the MinerAnts to maintain peak performance even during extended missions.

Operational Workflow

Deployment

- Launch: The MinerAnts and transport shuttles are launched from Earth aboard a mothership or directly from a space station. The deployment strategy is carefully planned to ensure that the robots are delivered to the target asteroid with minimal energy expenditure.

- Landing and Dispersal: Upon arrival, the MinerAnts are deployed to the asteroid’s surface. They disperse in a pre-programmed pattern to cover as much ground as possible, using their sensors to map the terrain and identify areas with high concentrations of valuable resources.

Exploration and Mapping

- Initial Survey: MinerAnts use their sensors to conduct an initial survey of the asteroid. This involves creating a detailed map of the surface, identifying potential hazards, and locating areas with high resource potential. The data collected during this phase is transmitted back to the mothership and Earth-based control centers for analysis.

- Dynamic Mapping: As the MinerAnts begin their operations, they continuously update the map with new data. This dynamic mapping capability allows the swarm to adapt to changing conditions and optimize their efforts in real-time.

Mining Operations

- Regolith Extraction: The MinerAnts commence regolith extraction, working together to efficiently collect and process materials. Each robot follows a specific protocol to ensure that the extraction process is both thorough and minimally disruptive to the asteroid’s surface.

- Material Processing: Extracted material is processed onboard the MinerAnts. The refined minerals are stored in secure compartments, while waste material is either discarded or used for other purposes, such as creating temporary shelters or barriers.

Material Transport

- Shuttle Operations: Processed materials are transferred to transport shuttles, which carry them to a central collection point or return modules. The shuttles operate autonomously, following pre-determined flight paths and utilizing advanced navigation systems to ensure precise landings.

- Return to Earth: Once sufficient resources have been collected, the return modules are launched back to Earth or a designated space station. The modules are designed to withstand the rigors of re-entry and ensure that the valuable cargo arrives safely.

Monitoring and Adaptation

- Continuous Monitoring: AI systems continuously monitor operations, adapting strategies based on real-time data. This includes adjusting the roles of individual MinerAnts, re-routing transport shuttles, and modifying extraction techniques to maximize efficiency.

- Learning and Optimization: The MinerAnts’ AI systems use machine learning algorithms to analyze the data collected during each mission. This allows them to identify patterns and improve their operations, becoming more efficient with each deployment.

Advantages

Scalability

- The modular and distributed nature of the swarm allows for easy scaling based on mission requirements. New MinerAnts can be added to the swarm at any time, enabling rapid expansion of mining operations without significant logistical challenges.

Resilience

- Distributed risk across thousands of robots ensures mission continuity even with individual unit failures. If a MinerAnt is damaged or malfunctions, the swarm can continue operating without significant disruption.

Cost-Effectiveness

- Small robots are cheaper to produce and maintain, and mass production can further reduce costs. The modular design also allows for easy upgrades and repairs, ensuring that the MinerAnts remain at the cutting edge of technology.

Efficiency

- Continuous, autonomous operation maximizes resource extraction with minimal downtime. The use of onboard processing and autonomous transport shuttles ensures that the entire operation is streamlined and efficient.

Challenges and Solutions

Coordination

- Challenge: Managing thousands of robots requires sophisticated coordination algorithms.

- Solution: Implement advanced AI and machine learning systems to enable seamless communication and task allocation. The use of decentralized algorithms ensures that the swarm can operate efficiently even in the face of unexpected challenges.

Power Management

- Challenge: Ensuring consistent power supply in variable lighting conditions.

- Solution: Utilize high-efficiency solar panels and advanced battery systems for effective energy management. The ability to track the Sun’s position and rapidly charge batteries ensures that the MinerAnts can operate continuously.

Durability

- Challenge: Protecting robots from harsh space conditions, including radiation and micrometeoroids.

- Solution: Construct robots from durable, radiation-resistant materials and design robust shielding. The use of advanced materials and protective coatings ensures that the MinerAnts can withstand the rigors of space.